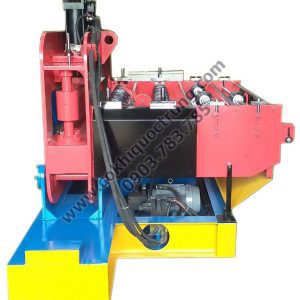

ROLL FORMING MACHINE 1 FLOOR 7 WAVES (IP CAMPUCHIA)

ROLL FORMING MACHINE 1 FLOOR 7 WAVES (IP CAMPUCHIA)

Bạn vui lòng nhập đúng số điện thoại để chúng tôi sẽ gọi xác nhận đơn hàng trước khi giao hàng. Xin cảm ơn!