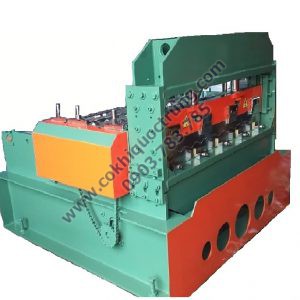

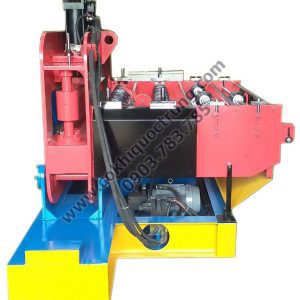

DOUBLE LAYER ROLL FORMING MACHINE

DOUBLE LAYER ROLL FORMING MACHINE

Bạn vui lòng nhập đúng số điện thoại để chúng tôi sẽ gọi xác nhận đơn hàng trước khi giao hàng. Xin cảm ơn!